Project Description

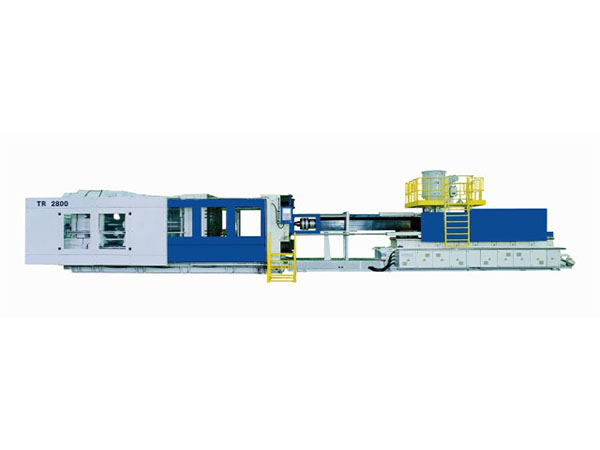

Large Size Injection Molding Machine

Large Size Injection Molding Machine(Clamping force from 850ton-1800ton)

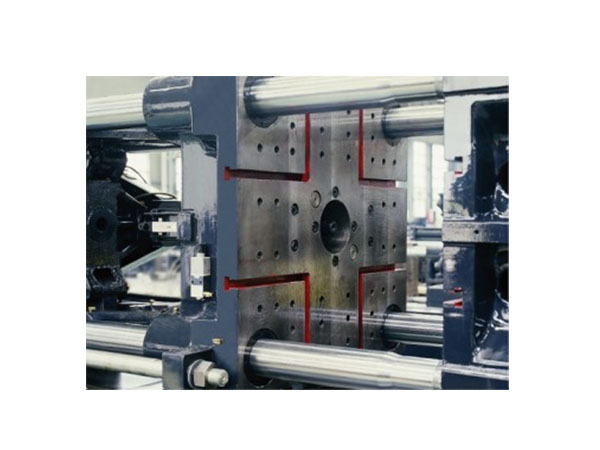

a) Five points tri-toggle clamping unit, finite-element analysis for platen design and modular structure guarantee rigidity of clamping as prolonged operation life.

b) Thread hole (Domestic) or T slot (Export) for varies mould setting.

c) Self-lubricated bushes in toggle system.* ELECTRIC UNIT

Model | TR850/850TON | TR1000/1000TON | TR1500/1500TON | TR1800/1800TON | ||||||||||

Unit | A | B | C | A | B | C | A | B | C | A | B | C | ||

INJECTION UNIT | Screw Diameter | mm | 90 | 100 | 110 | 100 | 110 | 120 | 120 | 130 | 140 | 130 | 140 | 150 |

Screw L/D Ratio | 24.4 | 22.0 | 20.0 | 24.2 | 22.0 | 20.2 | 23.8 | 22.0 | 20.4 | 23.7 | 22.0 | 20.5 | ||

Shot Size (Theoretical) | cm3 | 3238 | 3997 | 4836 | 4155 | 5027 | 5983 | 6774 | 7950 | 9220 | 9145 | 10606 | 12175 | |

Injection Weight | g | 2946 | 3637 | 4401 | 3781 | 4575 | 5444 | 6164 | 7235 | 8390 | 8322 | 9651 | 11079 | |

Injection Rate Into Air | cm3/s | 599/ 717 | 740/ 885 | 895/ 1070 | 698/ 811 | 845/ 981 | 1006/ 1168 | 872/987 | 1023/ 1058 | 1187/ 1343 | 1049/ 1153 | 1216/ 1337 | 1396/ 1535 | |

Injection Rate Into Air(ACC) | cm3/s | 1546 | 1909 | 2310 | 2923 | 3537 | 4210 | 3140 | 3685 | 4273 | 3151 | 3654 | 4194 | |

Injection Pressure | bar | 2184 | 1769 | 1462 | 2101 | 1736 | 1459 | 1955 | 1666 | 1437 | 1948 | 1680 | 1463 | |

Injection Stroke | mm | 509 | 529 | 599 | 689 | |||||||||

Screw Speed | rpm | 0~103/0~123 | 0~105/0~122 | 0~98/0~122 | 0~93/0~102 | |||||||||

CLAMPING UNIT | Clamping Force | KN | 8500 | 10000 | 15000 | 18000 | ||||||||

Clamping Stroke | mm | 1000 | 1100 | 1250 | 1520 | |||||||||

Space Between Tie Bar | mm | 1000×1000 | 1150×1150 | 1360×1200 | 1600×1480 | |||||||||

Max. Mold Height | mm | 1000 | 1100 | 1400 | 1550 | |||||||||

Min. Mold Height | mm | 350 | 400 | 600 | 650 | |||||||||

Eject Stroke | mm | 280 | 323 | 350 | 400 | |||||||||

Eject Force | KN | 212 | 282 | 282 | 407 | |||||||||

No. Of Ejector Pins | piece | 21 | 21 | 25 | 25 | |||||||||

OTHERS | Max. Pump Pressure | MPa | 16 | 16 | 16 | 16 | ||||||||

Pump Motor Power | KW | 37+45/45+55 | 45+45/55+55 | 55+55/55+75 | 55+75/75+75 | |||||||||

Heater Power | KW | 49.0 | 52.1 | 73.1 | 80.0 | |||||||||

Hopper Capacity | Kg | 160 | 200 | 200 | 200 | |||||||||

Oil Tank Capacity | L | 1500 | 2200 | 2500 | 2900 | |||||||||

Machine Dimension (L×W×H) | m | 10.8×2.72×2.75 | 12.1×2.88×3.54 | 13.7×3.2×3.64 | 15.6×3.5×3.7 | |||||||||

Machine Weight | T | 46.0 | 55.0 | 69.0 | 118.0 | |||||||||

a) Five points tri-toggle clamping unit, finite-element analysis for platen design and modular structure guarantee rigidity of clamping as prolonged operation life.

b) Thread hole (Domestic) or T slot (Export) for varies mould setting.

c) Self-lubricated bushes in toggle system.* ELECTRIC UNIT

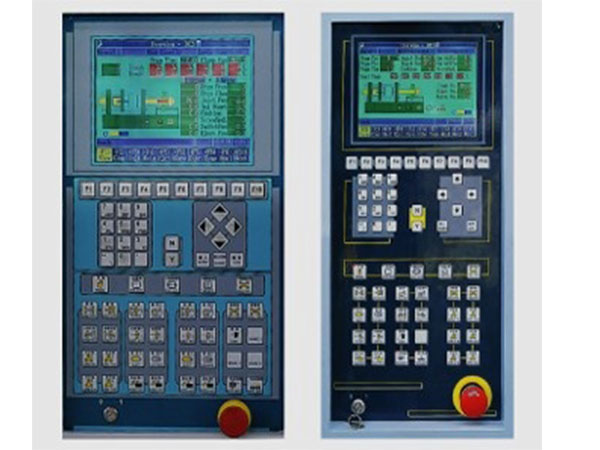

a) Waterproof cabinet. Electric parts from famous brands to ensure reliability.

b) Highly precise professional controller. Multiple languages were designed in machine computer.

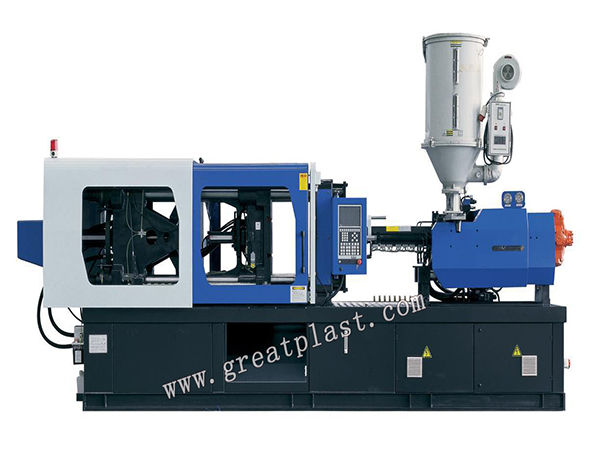

* Injection Unit

a) Specially designed nitride steel screws for PE, PVC &PET. Bimetallic screws fit for corrosive materials or fiber glass (Option).

b) Twin cylinder nozzle movement and balance both sides ensure no skewing on spray nozzle and no leaking of materials (standard for export).