Project Description

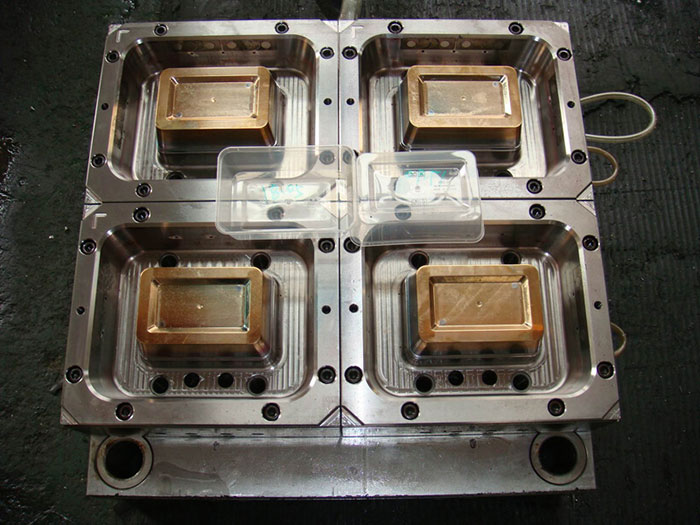

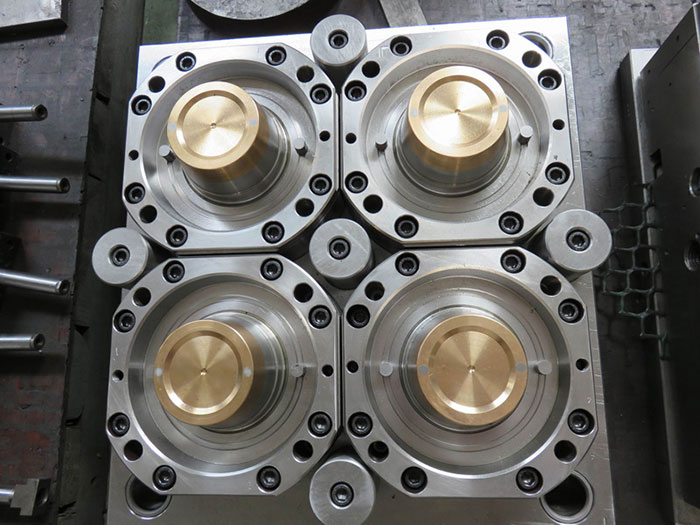

Cap mould

Cap mold,cap Mould,Mould,Plastic cap mould,Injection cap mould,Plastic injection cap mould,Moulding tool,Tool,Mold die,cap moulding tool, cap tool, cap mold die

Technical Features

1. Mould ranges from 1 cavity to 72 cavities.

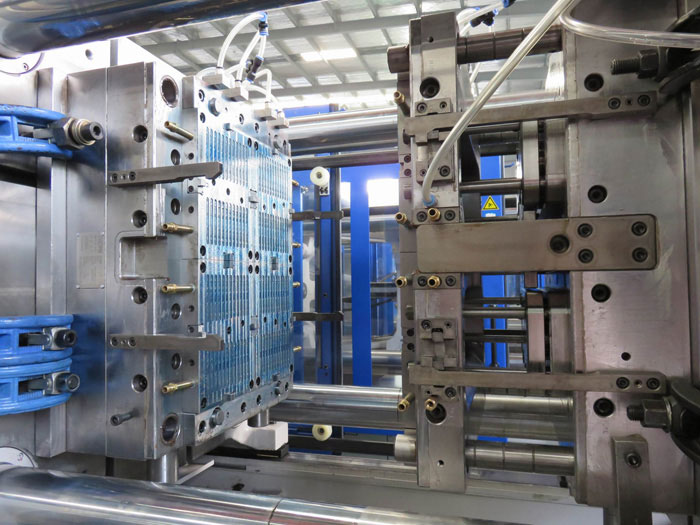

2. The mould plate is made of stainless steel.

3. Standard interchangeable mould components

4. High performance hot runner system ensures uniform melt flow and pressure in all cavities.

5. All of parts are manufactured by CNC equipments.

6. Advanced structure is designed consulting European cap mould.

7. Mould cavity and Core are made of steel with fine polishing, high hardness and anti-corrosion to get mold’s high precision and good quality.

8. Pneumatic drive the nozzle pin for simultaneous high-speed open and close actions.

9. Patent designed rectifying system is adopted to lessen the possible preform thickness problem happening during production.

10. Special designed water hoses eliminate leakage and water marks on preform.

11. Moldflow analysis reduce AA level.

12. Long using life over 2.5 million times of injection cycle.