Project Description

Precise and energy saving injection molding machine D100S

Precise and energy saving injection molding machine 100TON

* High efficiency

The efficiency of the traditional electromotor is very low, and the power factor will contribute to the loss of power. However, the servomotor doesn’t have this problem and will improve the efficiency by 10% than that of the traditional one.

Unit | D100S | |||||||

ITEMS | A | B | C | |||||

INECTION UNIT | Screw Diameter | mm | 35 | 38 | 42 | |||

Screw L/D Ratio | L/D | 21.7 | 20.0 | 18.1 | ||||

Shot Size(Theoretical) | cm3 | 168 | 198 | 242 | ||||

Injection Weight | g | 153 | 180 | 220 | ||||

Injection Pressure | MPa | 227.9 | 193.3 | 158.2 | ||||

Injection Rate into Air | cm3/s | 90.1 | 110.8 | 106.2 | 130.6 | 129.7 | 159.6 | |

Injection Stroke | mm | 175 | ||||||

Injection Speed | cm/s | 9.4 /11.5 | ||||||

Screw Speed | rpm | 218 /268 | ||||||

CLAMPING UNIT | Clamping Force | KN | 1000 | |||||

Clamping Stroke | mm | 360 | ||||||

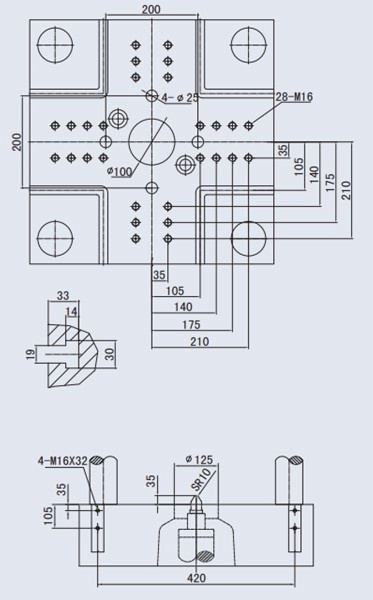

Space Between Tie Bar | mm | 360*360 | ||||||

Max. Mold Height | mm | 380 | ||||||

Min. Mold Height | mm | 150 | ||||||

Eject Stroke | mm | 120 | ||||||

Eject Force | KN | 34 | ||||||

No. Of Ejector Pins | piece | 5 | ||||||

OTHERS | Max. Pump Pressure | MPa | 17.5 | |||||

Pump Motor Power | KW | 11.0 | 15.0 | |||||

Heater Power | KW | 6.3 | ||||||

Hopper Capacity | Kg | 25 | ||||||

Oil Tank Capacity | L | 250 | ||||||

Weight | T | 3.2 | ||||||

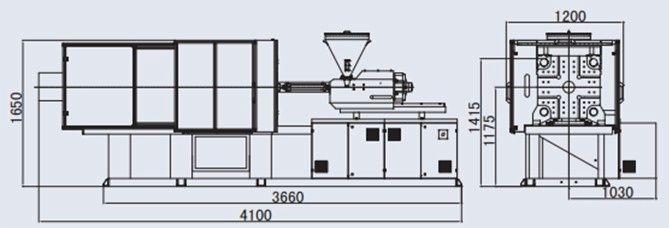

3. Machine size